ELECTRICAL SYSTEMS AND THERMAL IMAGINGInfrared (IR) thermal imaging has been used to inspect electrical systems for some time now and its use has steadily grown increasingly popular. Since components in electrical systems almost always overheat before they fail, problem areas are more easily and safely found when viewed through an infrared (IR) thermal imaging camera.

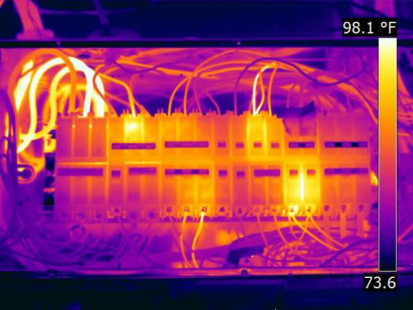

During an inspection, electrical equipment, such as distribution panelboards, switch boards, contacts, transformers, receptacles, and service and control panels, can be examined through an infrared (IR) thermal imaging camera. By viewing apparent temperature differences, we are able to identify and document problems, such as loose connections and overloaded circuits, which are the most common causes of electrical fires. Because viewing apparent temperature differences through an infrared (IR) thermal imaging camera requires no physical contact and can cover a lot of space in one sweep, no other technology allows electrical faults to be found as safely and as quickly as infrared (IR) thermal imaging.

Infrared (IR) thermal imaging cameras are commonly used for inspections of electrical systems and components in all sizes and shapes. The multitude of possible applications for infrared (IR) thermal imaging cameras within the range of electrical systems can be divided into two categories: high voltage and low voltage installations. DETECT HIGH-VOLTAGE FAILURESIn high voltage installations heat is an important factor. When electrical current passes through a resistive element, it generates heat. An increased resistance results in an increase in heat. Over time the resistance of electrical connections will increase, due to loosening and corrosion for instance. The corresponding rise in temperature can cause components to fail, resulting in unplanned outages and even injuries.

In addition, the energy spent on generating heat causes unnecessary energy losses. If left unchecked, the heat can even rise to the point where connections melt and break down; as a result, fires may break out. Examples of failures in high-voltage installations that can be detected with infrared (IR) thermal imaging:

An infrared (IR) thermal imaging camera will help to accurately locate the problem, determine the severity of the problem, and establish the time frame in which the equipment should be repaired.

One of the many advantages of infrared (IR) thermal imaging is the ability to perform inspections while electrical systems are under load. Since infrared (IR) thermal imaging is a non-contact diagnostic method, an infrared (IR) thermographer can quickly scan a particular piece of equipment from a safe distance, leave the hazardous area, return to his office and analyze the data without ever putting himself in harm’s way. DETECT LOW-VOLTAGE FAILURESInfrared (IR) thermal imaging cameras are used for inspections of electrical systems and components in all sizes and shapes and their use is by no means limited to large high voltage applications alone. Electrical cabinets and motor control centers are regularly scanned with an infrared (IR) thermal imaging camera.

If left unchecked, heat can rise to a point that connections melt and break down; as a result, fires may break out. Besides loose connections, electrical systems suffer from load imbalances, corrosion, and increases in impedance to current. Infrared (IR) thermal imaging can quickly locate hot spots, determine the severity of the problem, and help establish the time frame in which the equipment should be repaired. Examples of failures in low voltage equipment that can be detected with infrared (IR) thermal imaging:

These and other issues can be spotted at an early stage with an infrared (IR) thermal imaging camera. This will help to prevent costly damages and to avoid dangerous situations in your Kitchener, Waterloo, Cambridge, Guelph, Brantford & London area home or business.

Contact us at (226) 972-6440 to schedule an appointment today, or request an inspection online using the contact form. |

|

|

360 Inspection Services performs pre-purchase and pre-listing home inspections throughout Kitchener, Waterloo, Cambridge, Guelph, Brantford and London. We also provide mold & indoor air quality testing, radon testing, asbestos testing and infrared (IR) thermal imaging services.

|

|

Home Inspection Services | Mold Inspection Services | Indoor Air Quality Testing | Radon Testing | Asbestos Testing | Thermal Imaging | Waterloo | Kitchener | Cambridge | Guelph | Brantford | London | Ajax | Barrie | Brampton | Burlington | Caledon | Collingwood | Erin | Fort Erie | Halton Hills | Hamilton | Ingersoll | Innisfill | Markham | Milton | Mississauga | Newmarket | Niagara Falls | Norfolk County | Oakville | Orangeville | Orillia | Oshawa | Owen Sound | Peterborough | Pickering | Richmond Hill | Shelburne | St. Catherines | St. Thomas | Stratford | Tillsonburg | Thorold | Toronto | Vaughan | Wasaga Beach | Whitby | Woodstock

360 Inspection Services | All Rights Reserved © 2016